Umshini wokushaya isiyingiNgokuyinhloko yakhiwa ngohlelo lokuhlinzekwa kwe-yorn, indlela yokudonsela phansi, indlela yokudonsa futhi evuthayo, indlela yokuhambisa kanye nokuhlanza kanye nendlela yokulawula, ingxenye yokulawula kagesi, ingxenye ethile yokulawula.

1. I-Yarn Feeding Mechanism

Indlela yokudla ye-yorn nayo ibizwa ngokuthi yi-yorn feed mechanism, ehlanganisa i-creel, aI-Yarn feeder, noUmhlahlandlela we-Yarnkanye ne-yorn ring ubakaki.

Izidingo zomuthi wokudla we-yarn:

.

.

(3) Isilinganiso sokondla i-yarn phakathi kohlelo ngalunye lwe-knitting kumele lube khona. Inani lokudla kwe-yorn kufanele lishintshelwe ukuze lihlangabezane nezidingo zokushintsha kwemikhiqizo

.

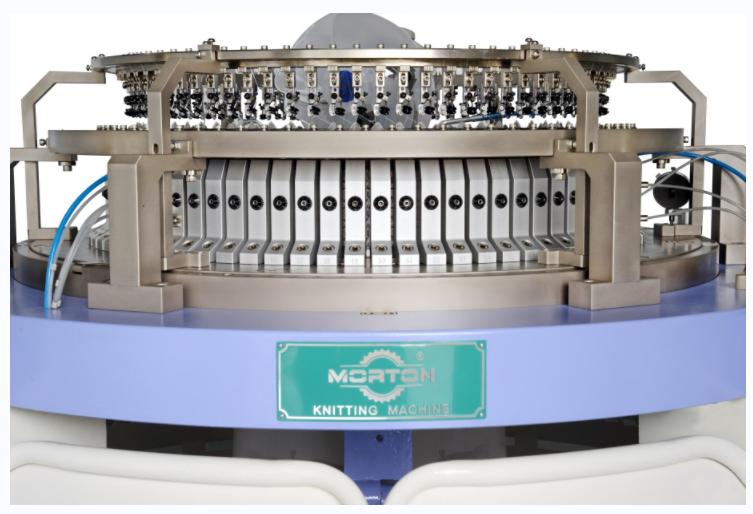

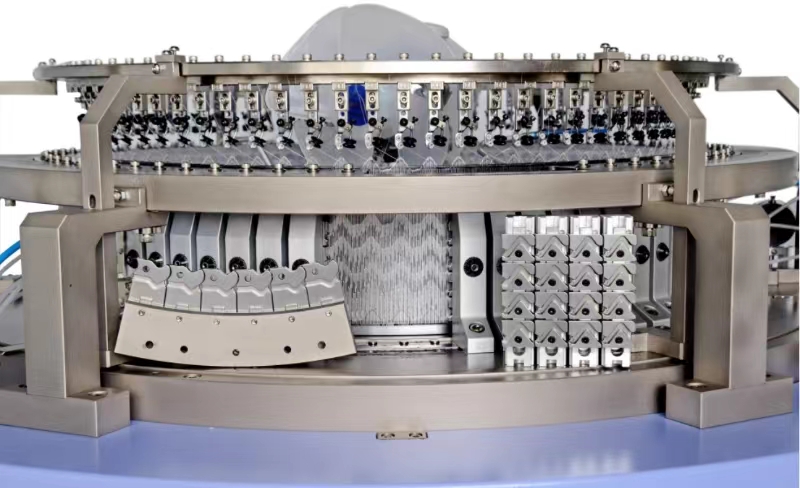

2. I-Knitting Mechanism

Indlela yokugoba yinhliziyo yomshini wokuvalwa oyindilinga. Ihlanganiswa ikakhulukaziIsilinda, ukubopha izinaliti, i-cam, isihlalo se-cam (kufaka phakathi isihlalo se-cam kanye ne-cam yenaliti yokugoba ne-sinker), i-sinker (eyaziwa kakhulu njengeshidi le-sink, swengke sheet), njll.

3. Ukudonsa kabusha kanye nokwenza umoya

Umsebenzi wendlela yokudonsa futhi evuthayo ukudonsa indwangu eboshwe endaweni yokugoba bese uyifaka ngefomu elithile lephakeji. Kufaka phakathi ukudonsa, ukugoqa i-roller, ukusakazeka uhlaka (olubizwa nangokubizwa ngendwangu yendwangu), ingalo yokuhambisa, kanye nokwenza ibhokisi legiya. Izici zalo

(1) Kukhona i-Sensor switch efakwe ezansi kwepuleti enkulu. Lapho ingalo yokuhambisa ifakwe nge-cylindrical nail pass, kuzokwenziwa isiginali ukukala inani lezinto zendwangu nenombolo yokuvukelwa.

(2) Setha inani lokuguqukela kwengxenye ngayinye yendwangu kwiphaneli yokulawula. Lapho inani lokuvukelwa komshini lifinyelela inani elisethiwe, lizoma ngokuzenzakalelayo ukulawula iphutha lesisindo sengxenye ngayinye yendwangu ngaphakathi kwe-0.5kg, okuzuzisa ukucubungula kokudaya. Nge-cylinder

.

4.Concoloniter

Ijubane eliguquguqukayo eliguquguqukayo eliguquguqukayo (motor) lilawulwa yisiguquli semvamisa, bese kuthi imoto ishayela igiya le-Shaft Shape futhi ngasikhathi sinye likudlulisela egiyeni elikhulu lepuleti, ngaleyo ndlela lihambisa umgqomo wetilonke. I-Shaft yokushayela ifinyelela emshinini oyindilinga oyindilinga bese ishayela indlela yokudla ye-youd.

5. Gcoba futhi uhlanze indlela ehlanzekile

Umshini we-knowititing knitting uyi-speed-speed ephezulu, ehlanganisiwe futhi eqondile. Ngoba intambo izodala inani elikhulu le-fly lint (i-lint) ngesikhathi senqubo yokugoba, ingxenye ephakathi egcwalisa i-knitting izohlushwa kalula ngenxa yokungenisa amandla ngenxa yokundiza amabala ngenxa yokundiza. Kuzolimaza imishini, ngakho-ke ukuthambisa kanye nothuli kwezingxenye ezinyakazayo kubaluleke kakhulu. Njengamanje, umshini wokudubula oyindilinga kanye nohlelo lokususa uthuli lubandakanya ama-Inductors amafutha, abalandeli be-radar, izesekeli zesekethe zamafutha, amathangi okuvuza kawoyela nezinye izinto.

Izici zezinqubo zokugcoba nokuhlanza

1. Umshini wokujova kawoyela okhethekile we-air fake unikeza ukuthambisa okuhle ebusweni bezingxenye ezinqunyelwe. Inkomba yezinga lamafutha kanye nokusetshenziswa kukaphethiloli kuyabonakala ngokuqondile. Lapho izinga lamafutha emshinini wokwelapha uphethiloli alwanele, lizovala ngokuzenzakalelayo lixwayise.

2. Umshini omusha we-auntueling wokuzenzakalelayo wenza ukusetha nokusebenza kube lula futhi kunembile.

I-3. I-radar fan inendawo yokuhlanza ebanzi futhi ingasusa ama-flake flakes kusuka kudivayisi yesitoreji ye-yorn kuya engxenyeni yokugoba ukugwema ukuhlinzekwa kwe-changn flow.

I-6.Control Mechanism

Indlela elula yokulawula inkinobho yokulawula isetshenziselwa ukuqedela ukusethwa kwamapharamitha okusebenza, ukuma okuzenzakalelayo kanye nokukhonjiswa kwamaphutha. Kuhlanganisa ikakhulukazi abaguquli bemvamisa, amaphaneli okulawula (abizwa nangokuthi amaphaneli okusebenza), amabhokisi okulawula ngogesi, imishini yokuthola iphutha, izintambo zikagesi, njll.

7.Ingxenye

Ingxenye yohlaka ifaka imilenze emithathu (ebizwa nangokuthi imilenze ephansi), imilenze eqondile (ebizwa nangokuthi imilenze ephezulu), ipuleti elikhulu, umnyango wokuvikela, umnyango ovikelayo kanye nesihlalo sokuvikela. Kuyadingeka ukuthi ingxenye ye-rack kumele ibenze futhi iphephe.

Isikhathi sePosi: Mar-09-2024